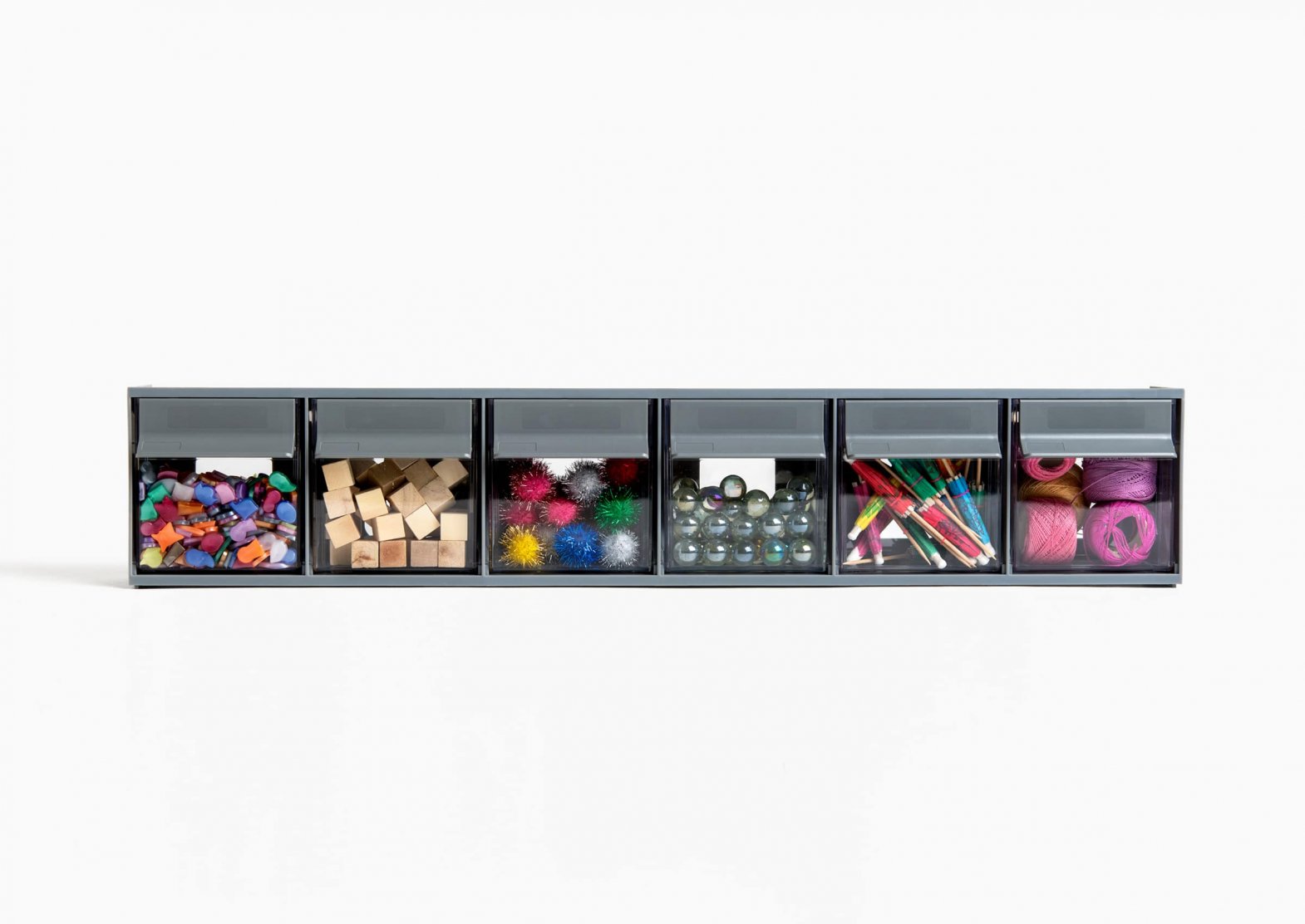

Tip Out Bin has been an iconic Huliot product for over 25 years. In 2016 Huliot decided to re-design the product in order to give it a competitive advantage over the competition.

During the brief definition stage of the project we defined two major problems with the old product:

The first problems was that due to the fact that the handle of the bins were sticking out of the product’s frame the handle became fragile and vulnerable to impact during shipping. Additionally, because the bin was manufactured as a monoblock with the container and handle injected as one piece, the entire bin was manufactured from polystyrene which was necessary due to its transparent qualities, but was unsuitable for a handle because it is fragile and brittle and resulted in high wear and tear.

The second problem was that the sticking out handle resulted in a bigger package, a crucial issue economic issue when considering containerization.

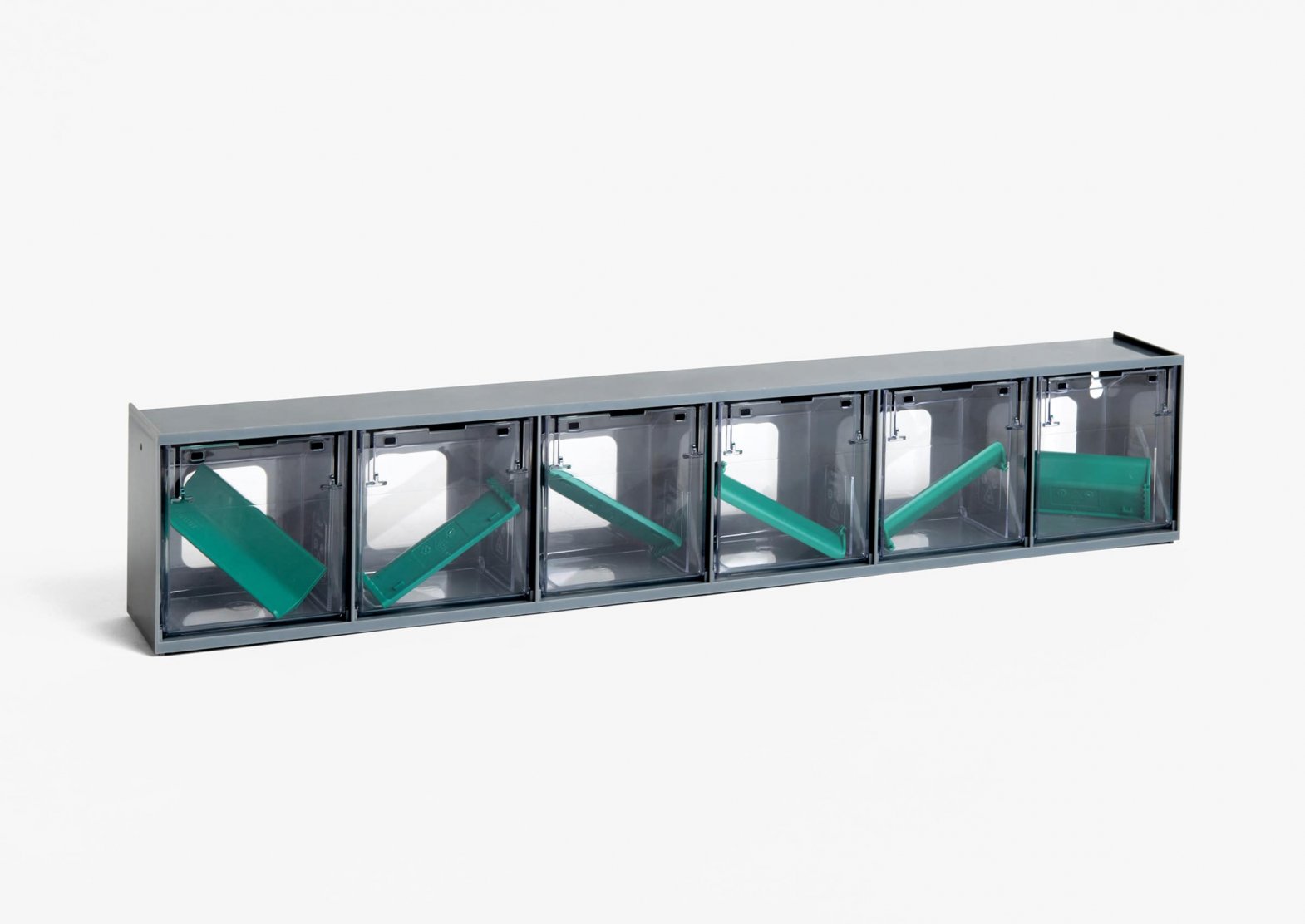

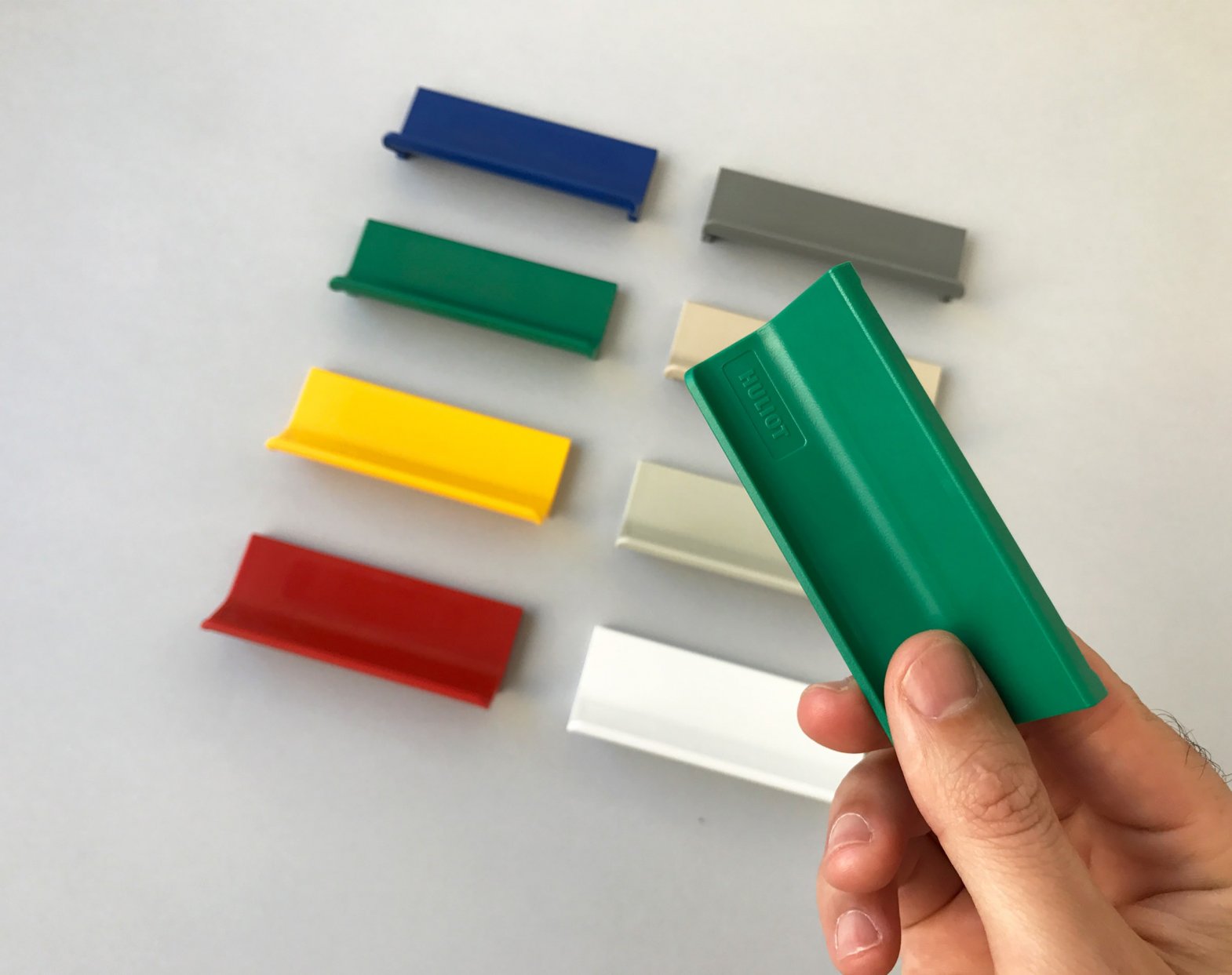

In order to solve these problems the studio redesigned the Tip Out Bin, as a bin with a detachable handle which enables storage of the handle within the bin during shipping and easy assembly once reaching the client. This solution both make the package smaller (and therefore more efficient and economic), and prevents damage to the handle both during shipping and during usage, because manufacturing the handle separately enabled it to be manufactured from a ABS which is more durable to impact.

An added value of the detachable handle, which comes in a variety of colors is the possibility to use it visual inventory and color coding tool.

Visually, the goal of the design was to create a fresh and updated look for a familiar and loved product and keep the product’s iconic visual values and functional requirements.

The design of the product included the development of a patent pending joinery authored by the studio.

Mechanical concept sketches.